Characterisation & Microscopy

R-TECH Materials is an accredited testing laboratory that can help you characterise the structure of a wide range of materials using a diverse range of techniques. To find out more about our services, contact us today.

Characterisation and Microscopy is a routinely used analysis technique to examine the macrostructure and microstructure of materials. R-TECH has a range of techniques at its disposal for the characterisation of materials, but our main technique involves imaging by the means of optical or electron microscopy.

Microscopy

Our microscopy suite, including a HIROX digital microscope can be utilised for a wide range of materials to characterise properties such as:

- Phase

- Void content

- Grain structure

- Particle size

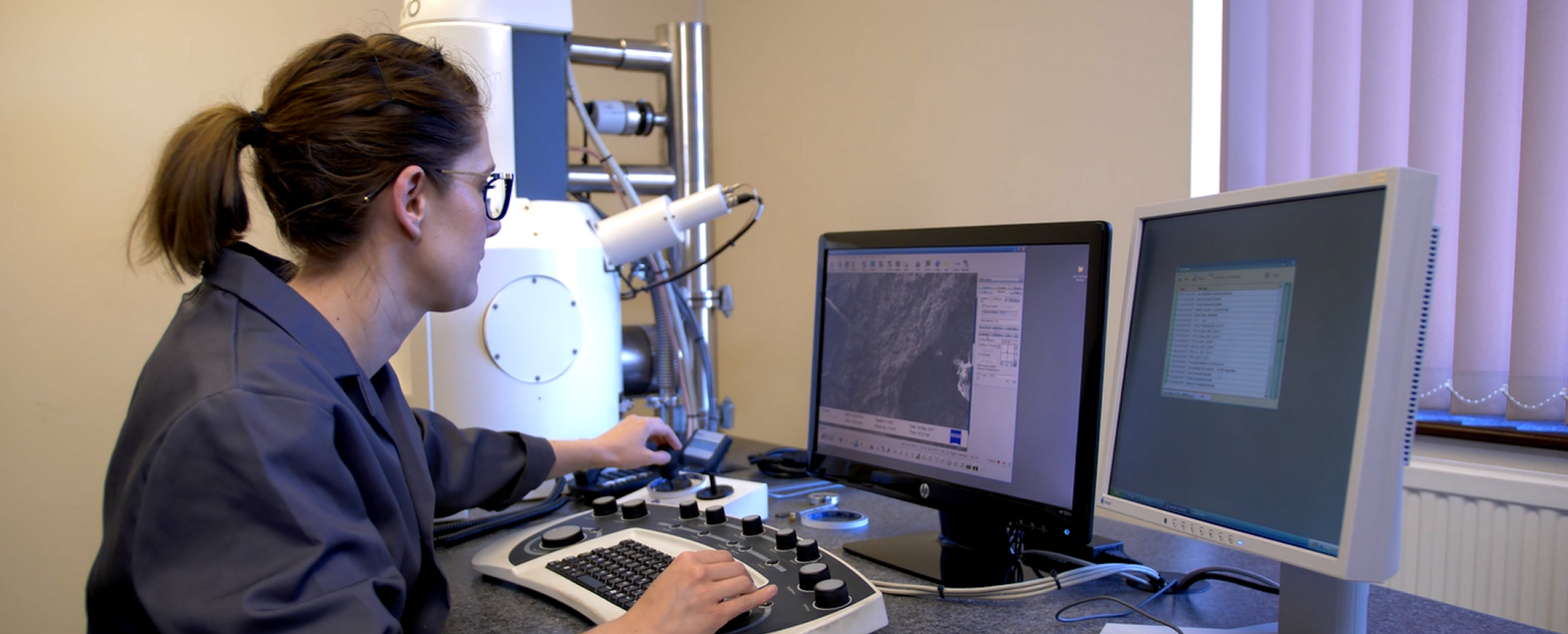

SEM

The in-house Zeiss EVO 60 scanning electron microscope with Oxford INCA EDX microanalysis system enables magnification up to X50,000. This powerful imaging technique used for metallic and non-metallic materials is widely used for the examination of fracture surfaces, corrosion products, material defects etc. The Oxford INCA microanalysis system can also be used to identify the elemental composition of local areas on the specimen surface. This is an invaluable tool for the identification of corrosion products, contamination, identification of defect sources etc.

We can also use other characterisation techniques that includes thermal analysis, surface texture, dimensional measurement, particle size distribution, thermal conductivity, fibre content, water absorption, coating thickness, and many others!

Physical Properties

- Specific Gravity / Density

- Absorption of liquids (oils, water, acids)

- Non-volatile content

- Shrinkage Measurement

- Viscosity

- Gel time

- Dimensional tolerance measurement

- pH

- Particle Size

- Void content

Thermal Properties

- Differential Scanning Calorimetry – DSC

- Dynamic Mechanical Analysis – DMA

- Thermogravimetric Analysis – TGA

- Thermal Mechanical Analysis – TMA

- Temperature Deflection Under Load – TDUL

Thermogravimetric Analysis

- Loss of water

- Loss of solvent

- Decarboxylation

- Oxidation

- Decomposition

- Filler Content

- Non-Volatile Content

- Vapourization

- Sublimation