Reinforcing Steel

As a global leader for testing rebar and other reinforced steel products, our range of products can provide you with high quality results. We are on hand to be your experts in this field, to find out more give us a call today on 01656 748000.

R-TECH Materials are recognised globally as one of the leading specialist laboratories for testing rebar and other related reinforced steel products! We have the capacity to test the full range of products, but our scope covers loads up to 1500kN (beyond the breaking load of 50mm reinforcing bar).

With Dr Tony Franks playing a pivotal role in the development of national and international standards for rebar, our team of engineers and materials scientists share many decades of experience in the reinforcing steel industry. This includes not only the testing of reinforcing steel and related products but also manufacture, quality assurance, research and development. We aim to harness this expertise to add value to the work that we deliver, providing additional consultancy services where required.

Alongside providing our expertise and testing capabilities to reinforcing steel mills across the world, R-Tech’s team work with product manufacturers and fabricators of couplers, anchors, strand and welded products. Our services include characterisation and bespoke testing as well as consultancy and product development. In addition to these commercial projects, R-Tech has also commissioned and sponsored several research and development projects in the steel for concrete structures sector.

Our reinforcing steel laboratory is UKAS accredited to provide our clients with confidence that their testing data is accurate and reliable. Below you can find the tests by type which are accredited within our quality management system.

- BS EN ISO 6892-1:2009 (Method B)

- ASTM A370-16

- BS 4449:1997 (Superseded)

- BS 4449:2005+A3:2016

- BS 4482:1985 (Withdrawn)

- BS 4482:2005

- BS 4483:1998 (Withdrawn)

- BS 4483:2005

- BS 4486:1980

- BS 6744:2001

- BS EN ISO 15630-1:2010

- BS EN ISO 15630-2:2010

- BS EN ISO 15630-3:2010

- ASTM A370-16

- ASTM A615/A615M-16

- ASTM A706/A706M-16

- BS 4449:1997 (Superseded)

- BS 4449:2005+A2:2009

- BS 6744:2001

- BS EN ISO 15630-1:2010

- BS EN ISO 15630-2:2010

- BS EN ISO 15630-3:201

- BS 6744:2001

- ASTM A370-14

- ASTM A615/A615M-09b

- BS 4482:1985 (Withdrawn)

- BS 4482:2005(2012)

- BS 4449:1997 (Superseded)

- BS 4449:2005 + A3:2016

- BS EN ISO 15630-1:2010

- BS EN ISO 15630-2:2010

- BS EN ISO 15630-3:2010

- ISO 7801:1984

- Elemental Analysis by documented in house method APM03 using OES (Spectromax – X)

- Carbon and Sulphur by documented in house method APM 04 using Leco CS 244 analyser

- Nitrogen by documented in house method APM 05 using Leco TN 114 analyser

- Determination of Geometrical Characteristics – BS EN ISO 15630-1:2010

- Relative Rib Area – BS EN ISO 15630-2:2010

- Deviation from normal mass per metre – BS EN ISO 15630-3:2010

- Macro examination by documented In-House Method PM23

- BS EN ISO 6507-1:2005

- BS EN ISO 9015-1:2011

- BS EN ISO 15614-1:2004

Static Testing

Our universal testing machines have all the necessary technology for testing reinforcing bar for all sizes up to 50mm (1.5MN). These machines can facilitate testing to British, European, ISO standards as well as the national standards of other nations with extensometry for accurate strain measurement.

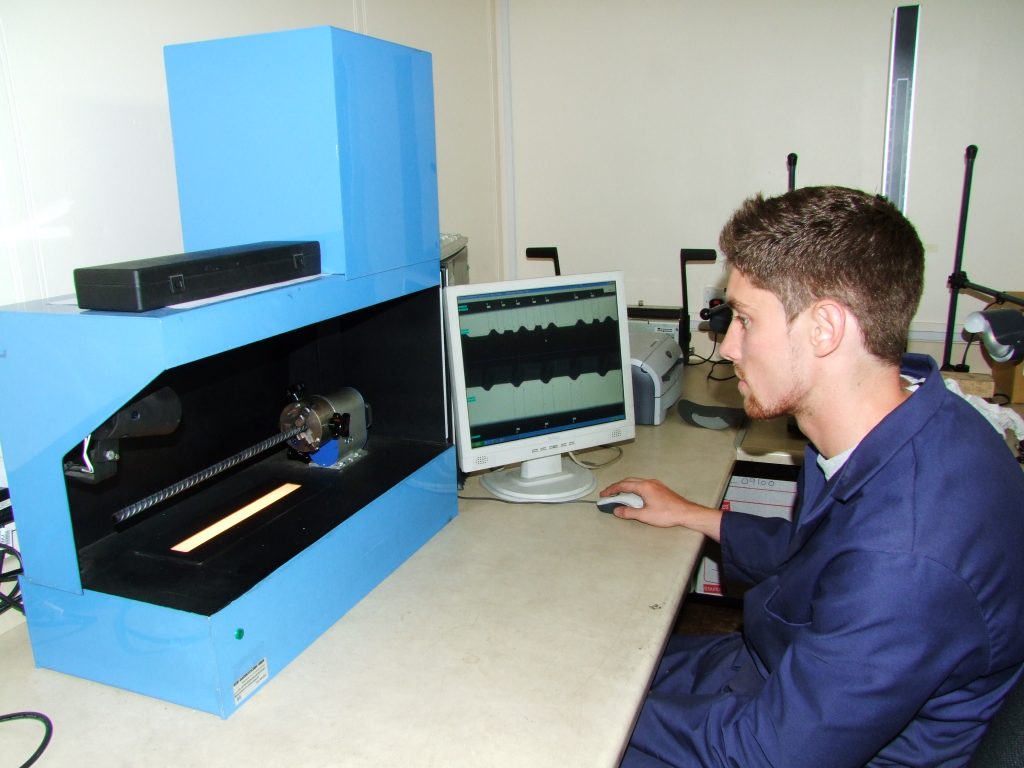

Fatigue

Our specialist rebar fatigue laboratory is a world leader and as such we receive fatigue testing samples from steel mills all over the world. We can test to standards for Britain, Germany, Holland, Singapore, Malaysia, USA and many others with capacity up to 400kN. Alongside a full suite of electro-magnetic resonance machines, we also have a servo-hydraulic test machine where complex loadings, through-zero loading or reduced frequency testing are required.

Chemical Analysis & Characterisation

Alongside these mechanical testing facilities, the in-house chemical and characterisation laboratories provide facilities to meet further testing requirements such as:

- Rib geometry

- Hardness

- Carbon, Sulphur, Nitrogen

- OES for other alloy elements and impurities

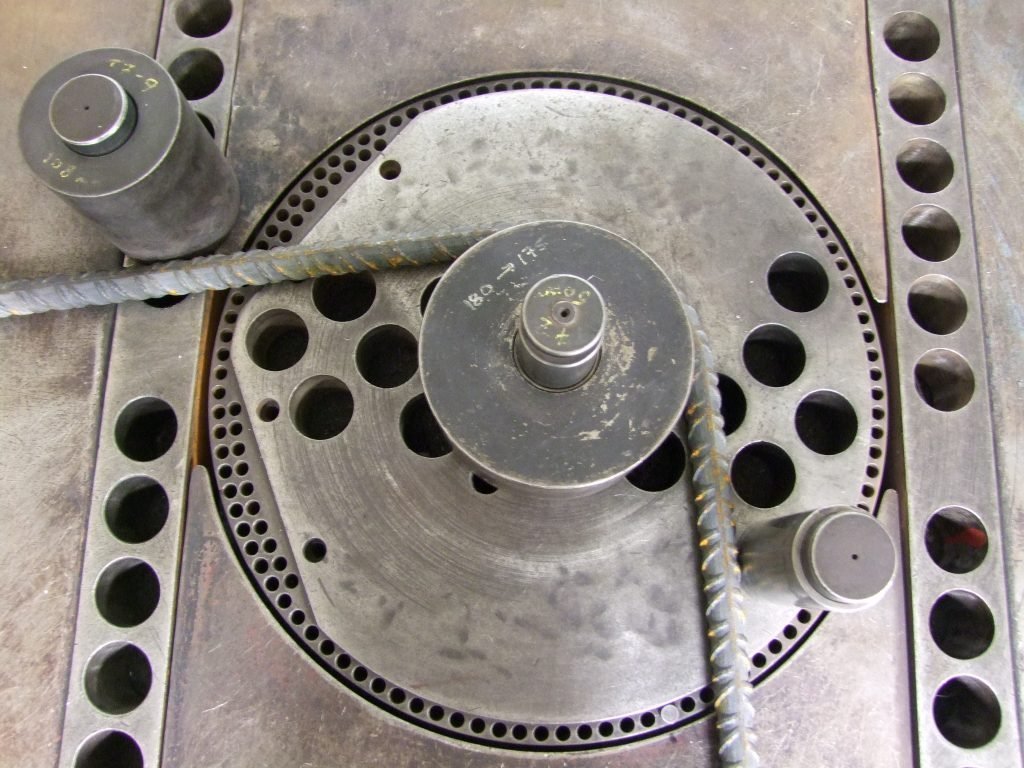

Bend / Rebend

Many national standards require a bend or rebend test. The rebend test requires an ageing heat treatment between the bend and rebend stages. Different standards specify different mandrel diameters, as a means of determining the severity of the bend. This simple test ensures the integrity of the bar when bent during fabrication and can be performed on all sizes of rebar up to 50mm.

Resources

Steel for Concrete Structures Summary

Download a simple one-page summary of our Steel for Concrete Structures services.